Silicone and rubber gaskets are commonly used in various industries. They serve the important purpose of creating a seal between two surfaces, preventing leaks, and ensuring the proper functioning of machinery and equipment. It can be hard to figure out which material is best for your needs because they both have their own qualities and benefits.

In this article, we will go over the differences between silicone and rubber gaskets and talk about some essential factors you need to consider before choosing one.

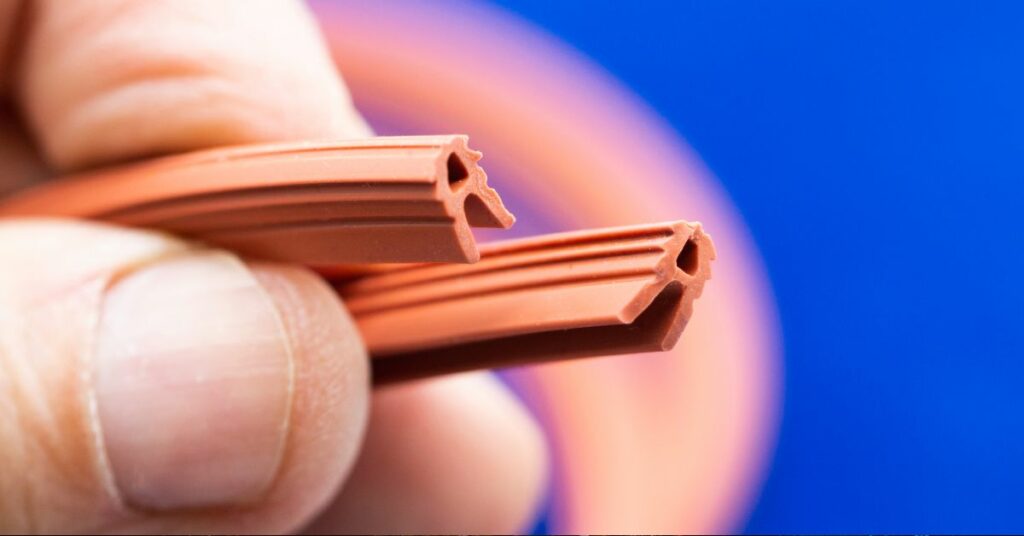

It is important to know the difference between silicone and rubber to choose the right gasket material. These two materials have some significant differences that can impact their performance in various applications. Here are the differences between silicone gaskets and rubber gaskets:

When it comes to the raw composition of these two materials, they are very different from each other. And the same goes for their different variations.

Rubber is available in both natural and synthetic forms. Natural rubber is derived from the latex sap of rubber trees and contains poly(cis-1,4-isoprene), a polymer of isoprene units. On the other hand, synthetic rubber is created by combining different monomers, often derived from petroleum, using distinct polymerization processes.

Examples of common synthetic rubbers include styrene-butadiene rubber and neoprene. Rubber, in general, exhibits high elasticity and flexibility.

Silicone, on the other hand, is composed of atoms of silicon, oxygen, carbon, and hydrogen, forming a polymer known as polysiloxane. The siloxane monomers are polymerized to create silicone.

The polymerization gives it unique properties such as electrical insulation, chemical resistance, and thermal stability. Silicone rubber, like rubber, is also elastomeric and has the ability to rebound to its original form after stretching.

Rubber is popular for its excellent elasticity and flexibility. It can withstand repeated flexing and stretching without losing its structural integrity. This makes rubber gaskets suitable for applications requiring much movement and flexibility.

On the other hand, silicone gaskets may not be as elastic as rubber. Although they have some degree of flexibility, they may not be able to withstand the same level of repeated flexing. Thus, silicone gaskets are more suited for applications that do not require a lot of flexing.

When it comes to resilience to temperature extremes, silicone often outperforms rubber. Silicone has a broader temperature range, allowing it to tolerate both higher and lower temperatures. This makes silicone gaskets suitable for applications where temperature fluctuations are common.

On the other hand, rubber may have limitations when it comes to extreme temperatures. Its structural integrity may be compromised when exposed to high or extremely low temperatures. Therefore, silicone gaskets would be a better choice if your application involves temperature variations.

Silicone gaskets exhibit superior resistance to UV radiation, ozone, and severe weather conditions compared to rubber gaskets.

Rubber gaskets are more susceptible to damage from UV radiation, ozone exposure, and extreme weather conditions such as rain, snow, or intense sunlight. On the other hand, silicone gaskets are popular for their durability and resistance to these environmental factors.

Regarding chemical resistance, silicone rubber often outperforms other types of rubbers. Silicone gaskets have excellent resistance to a wide range of chemicals, including solvents, acids, oils, and fuels. This makes them suitable for applications where there will be exposure to various chemicals.

Rubber gaskets may offer some level of chemical resistance but may not be as effective as silicone when it comes to withstanding harsh chemicals or corrosive substances.

Selecting the right gasket material is essential for sealing applications. Two common options are rubber and silicone gaskets. Here are some factors to consider when deciding between these two materials:

The industry your project falls under, such as automotive, aerospace & defense, industrial, marine, or engineering, will largely determine the environmental conditions the gasket material will be exposed to.

Different industries may have specific requirements for gasket materials, so it's important to choose accordingly.

Consider the physical attributes that are crucial for your project. Factors such as flexibility, compression set, elasticity, tensile strength, hardness, or density may play a role in determining the suitability of a gasket material.

For example, rubber gaskets are often chosen for their elasticity and flexibility, making them suitable for applications requiring the material to stretch without permanently deforming.

Suppose your application involves exposure to chemicals, oils, or fuels. In that case, choosing a gasket material that won't deteriorate, swell, or break down is essential. Due to their inertness, silicone gaskets have use in applications which require high resistance to oils and chemicals.

They offer excellent resistance to a wide range of chemicals, making them a preferred choice in many industries.

The projected operating temperature range of the gasket's intended environment is another important factor to consider.

Silicone gaskets have excellent temperature stability. Their properties remain intact across a wide range of temperatures. They can withstand both high and low temperatures without losing their sealing capabilities.

Choosing a durable and long-lasting gasket material can save you money on future maintenance and repairs. Both rubber and silicone gaskets offer good wear resistance. Still, the specific demands of your application will determine which is more suitable.

Consider factors such as the frequency of use, exposure to harsh conditions, and expected lifespan of the gasket to ensure optimal performance and longevity.

While rubber gaskets are generally more affordable than silicone ones, it's important to consider both the initial cost and potential long-term savings based on the performance and longevity of the materials.

Cheaper upfront costs may be tempting, but if the gasket needs frequent replacement or fails to meet your application's requirements, it could cost you more in the long run.

Silicone gaskets offer excellent resistance to extreme temperatures, chemicals, and UV radiation, making them suitable for a wide range of industries. On the other hand, rubber gaskets provide excellent compression and sealing properties, making them ideal for high-pressure sealing applications.

Both silicone and rubber gaskets have their own unique advantages and disadvantages, and the decision ultimately depends on the exact needs of your project.