Silicone rubber sheets are one of the most versatile materials out there. It can be found in a wide variety of daily-use products like cooking or baking tools, stylish undergarments, sportswear, or even repairs to your home or electronics.

Manufacturers favor food-contact-safe heat-resistant properties, durability, and non-stick characteristics. The cherry on top? It's a food-contact safe material, making it an excellent option for food storage containers.

Rubber and silicone are both elastomers, but they have very different properties. Rubber is highly elastic and made from the sap of rubber trees, but it degrades under extreme temperatures and cannot withstand chemicals.

On the other hand, a synthetic rubber sheet can withstand extreme temperatures and chemical exposure. They are, therefore, ideal for use in medical, food, and electronics applications.

You'll be amazed at how much noise and vibration silicone rubber sheets can eliminate - like magic. Not only are they incredibly flexible, but they also have outstanding thermal properties.

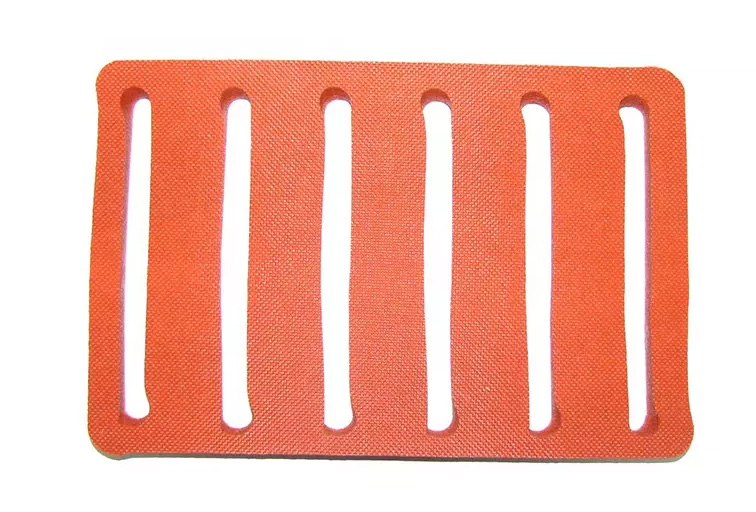

These sheets are perfect for all sorts of tasks, whether you need to insulate, seal, or create gaskets. One of the greatest advantages of these sheets is their adaptability. They can mold perfectly to any situation.

Silica rubber sheets create a peaceful, quiet space that is free from loud and annoying sounds. They are the ideal solution for all of your noise reduction needs.

Proper storage is crucial in keeping your silicone rubber sheets in top shape for the long haul. The key is to follow the "Guidelines for storage - Rubber products" found in the BS ISO 2230-2002 Specification.

These guidelines will help you inspect, record, package, and store your rubber products correctly. By observing this, you can guarantee that your silicone rubber sheets stay in excellent condition, providing you with dependable and long-lasting performance.

Both FDA and Canada have given their stamp of approval to silicone rubber sheets for use in medical products and cooking ware. However, the European Union has raised concerns about some of the chemicals used during its production.

While recent studies suggest that silicone rubber can leach certain chemicals under specific circumstances, it still proves to be a reliable, flexible, long-lasting, and heat-resistant material, perfect for many applications.

Silicone rubber sheets are made up of a unique and versatile material known for their remarkable resilience under extreme conditions. This incredible material can withstand temperatures ranging from extremely low to extremely high, making it very useful in various applications.

Some silicone rubber grades are engineered to remain flexible even at temperatures as low as -100°C and as high as 315°C. This means that silicone rubber sheets maintain their flexibility and elasticity even after being exposed to temperature extremes.

When it comes to using silicone rubber as a building material, there's one major downside to consider: poor tear strength. But don't count it out just yet, because adding other ingredients can actually improve its tear strength.

Keep in mind though, that silicone isn't naturally strong or resistant to abrasion. That's why it's important to carefully evaluate whether it's the right material for your specific application before making a decision.

Silicone can lasts much longer in the environment and in products compared to plastic. It's made from silica, which is found in sand, and that's its main ingredient.

Another great thing about silicone is that its surface can endure extreme temperatures, from extremely cold to hot, without cracking, melting, bubbling, or otherwise degrading due to these fluctuations.

When connecting silicone rubber sheets to steel parts, a crucial step is to cut the rubber material profile in a dovetail joint- this technique creates a strong bond between the two materials. After buffing the material, it's important to apply a liquid vulcanization compound to further enhance the bond.

As the adhesive cures under pressure and heat, the bond becomes even more durable and long-lasting. Using this seamless method, you can ensure reliable and secure connections between silicone rubber sheets and steel parts.

As you select silicone rubber sheets, make sure to factor in the friction and thermal expansion coefficient ratios. Thermal expansion indicates how the sheet's length might change under varying temperatures, while friction ratio determines how much force you'll need to move the sheet.

Under different temperatures, these ratios can drastically impact the sheet's ability to grip surfaces and maintain its shape. Don't forget to keep these factors in mind as you choose the perfect sheet for your application.