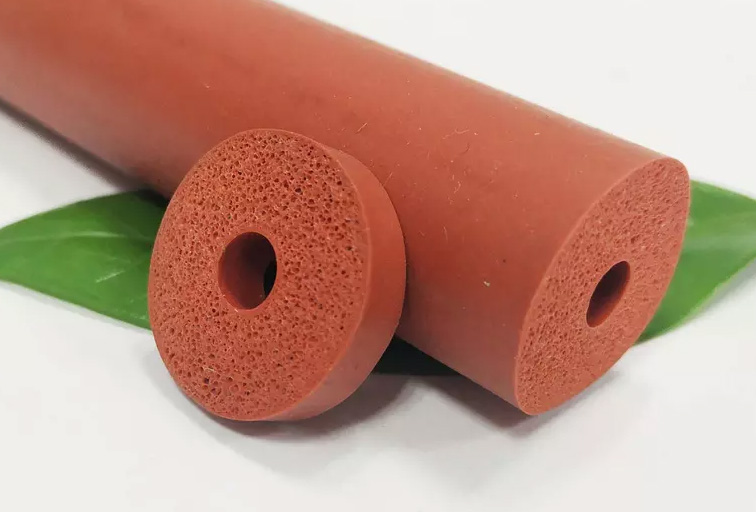

Have you ever wondered how silicone foam is made? Well, first off, it all starts with a liquid silicone rubber that has a low viscosity. This makes it much easier to pump the liquid into the vulcanization machinery where the magic happens.

Next, the material is taken through curing ovens where it solidifies into a foam. This step helps achieve a very refined and smooth surface finish, which is one of the reasons why silicone foam is such a popular choice for many applications.

This material is perfect for cushioning and preventing dust or light water from getting in. Because of its unique structure, it allows air to pass through, which makes it a great option for applications where breathability is important.

Not only that, but silicone foam is also great for outdoor and wash-down gaskets because of its impressive water-resistant properties. It's tough enough to handle even the harshest conditions and can be used as a resilient cushioning pad.

Silicone foam is an incredibly versatile material that's widely used in various applications. It's commonly employed for insulation, seals, and gaskets due to its exceptional heat and moisture resistance. This makes it ideal for use in electronic devices, construction materials, and automotive parts.

In contrast, Polyurethane foam (PU) is mostly known for its cushy feel and added comfort. It's often found in items such as mattresses, furniture, and cushioning materials, making them all the more comfortable.

In most cases, you can expect PU to hold up anywhere from 5 to 10 years, while silicone joints can outlast them, lasting more than two decades. It's important to note that PU has an advantage in applications that require resistance to wear and tear, thanks to its quality and hardness.

On the other hand, silicone joints are ideal for projects that demand flexibility and can withstand extreme temperatures. Ultimately, the choice between polyurethane and silicone hinges entirely on the specific needs of the project at hand.

Silicone foam is perfect for making gaskets that need to be resistant to water. This is because of its closed-cell structure. It can be used for outdoor gaskets as well as wash-down gaskets.

In addition to being water-resistant, silicone foam is also very heat-resistant. It can withstand temperatures anywhere between -60°C to 230°C. This makes it the perfect material for high-temperature pipes and HVAC systems because of its high thermal conductivity.

Silicone sealants are the go-to solution for waterproofing needs that can last for decades. But, did you know that external factors such as exposure to UV radiation, surrounding temperature, and even the chemical properties of the materials being sealed can affect the longevity of the adhesive? It's true!

On the bright side, when it comes to selecting the best type of polyurethane or silicone foam for a project, it all depends on the specific needs of that project. Factors such as flexibility and ability to withstand extreme temperatures are taken into consideration before making a final decision.

The cells of silicone sponges are interconnected and do not allow for the flow of air or water, making it an excellent choice for applications that require sealing or cushioning.

Silicone foam has interconnected cells and allows for air and water flow, making it ideal for applications that require sound absorption, thermal insulation, or vibration damping.

Silicone is an incredibly versatile material that you can use in a variety of ways like in medicine, cooking, and electrical equipment. One of the reasons it's so popular is that it's chemically stable which means that it's super safe to use, and you don't have to worry about it being toxic.

But that's not all. Silicone foam has a fantastic temperature range, and it's also resistant to oil and chemical deterioration. This makes it a solid choice for many different applications.

Usually, when plastics are exposed to high temperatures, they tend to melt and become soft. However, the case is different for silicone. Unlike most plastics, silicone doesn't have a melting point. This means that it will remain in a solid state until combustion occurs.

That being said, if silicone rubber is exposed to high temperatures ranging between 200-450°C, it might slowly lose its mechanical properties over time, thus becoming brittle. Despite that, it won't melt like other plastics do.